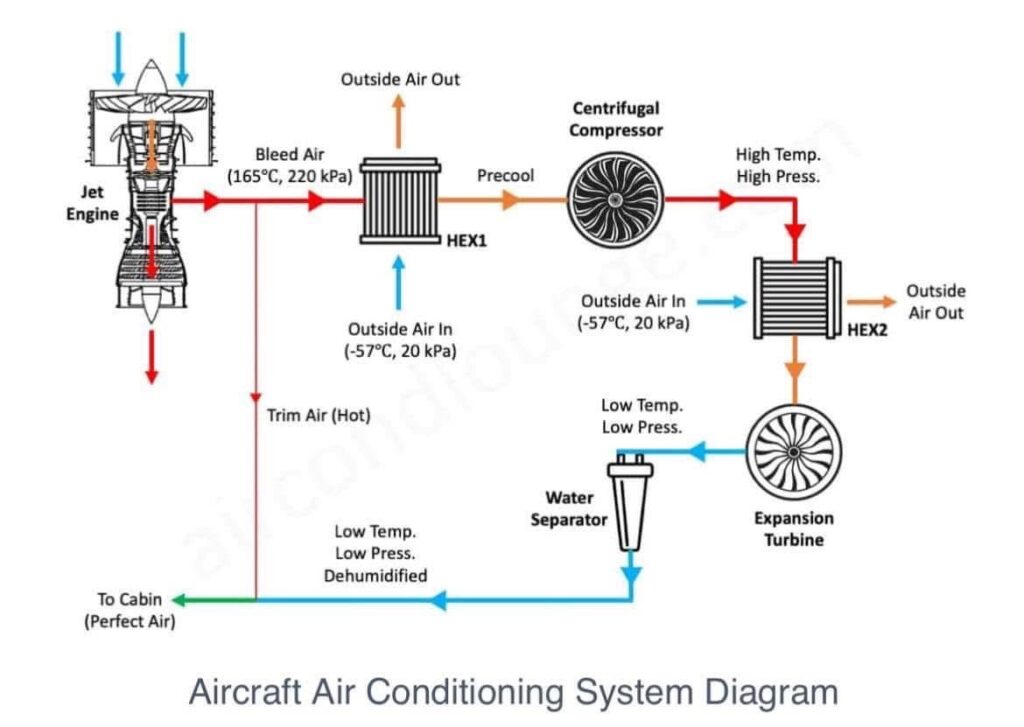

Aircraft Air Conditioning System

The process of an aircraft air conditioning system, which conditions and supplies air to the cabin to maintain a comfortable environment. Here’s a step-by-step breakdown of the process:

1.Bleed Air Extraction : 👇

- Air is extracted from the jet engine as “bleed air,” which is at a high temperature (165°C) and high pressure (220 kPa). This hot, pressurized air is tapped directly from the engine.

2.First Heat Exchanger (HEX1) : 👇

- The hot bleed air passes through the first heat exchanger (HEX1), where it is precooled by outside air that is drawn in at a very low temperature (-57°C) and low pressure (20 kPa).

- Some of the outside air is also vented out after absorbing heat from the bleed air.

3.Centrifugal Compressor : 👇

- After precooling, the air is directed to a centrifugal compressor. Here, the air is compressed, which increases its temperature and pressure again.

4.Second Heat Exchanger (HEX2) : 👇

- The hot, high-pressure air from the compressor flows into the second heat exchanger (HEX2), where it is further cooled by outside air at -57°C and 20 kPa.

- Excess outside air is vented out after cooling the bleed air.

5.Expansion Turbine : 👇

- After cooling in HEX2, the air reaches the expansion turbine, where it undergoes rapid expansion, reducing its temperature and pressure further. This step cools the air significantly, preparing it for cabin use.

6.Water Separator : 👇

- The cooled, low-pressure air passes through a water separator, which removes moisture from the air to prevent cabin fogging and maintain dryness.

7.Trim Air and Cabin Supply : 👇

- The dehumidified, cooled air is then routed to the cabin as “perfect air.” A portion of hot “trim air” from earlier in the process may be mixed in to fine-tune the temperature to the desired level before reaching the cabin.

This cycle ensures that the air supplied to the cabin is at an optimal temperature, pressure, and humidity for passenger comfort.